The Role of Membrane Switch Technology in Improving Product Interfaces

The Role of Membrane Switch Technology in Improving Product Interfaces

Blog Article

The Advantages of Using Membrane Layer Switches in Consumer Electronic Devices

Membrane buttons are increasingly acknowledged for their considerable benefits in customer electronics, particularly in improving customer interaction and enhancing production processes. The convenience in layout allows for tailored solutions that fulfill diverse customer requirements.

Boosted User Experience

In today's competitive landscape of consumer electronics, enhanced individual experience is vital; almost 85% of customers prioritize user-friendly user interfaces. Membrane layer switches over play a critical role in attaining this level of use. Their level, inconspicuous design permits smooth assimilation into numerous tools, lowering mass while keeping performance. This style aesthetic not just enhances the aesthetic allure but additionally adds to a much more structured individual communication.

The tactile responses offered by membrane buttons is vital for guiding customer activities, guaranteeing that commands are signed up accurately. This feedback mechanism lessens mistakes and heightens customer satisfaction, promoting a positive connection between the user and the device. Moreover, the adjustable nature of membrane layer switches over permits makers to customize user interfaces to specific user requirements, making devices a lot more available and inviting.

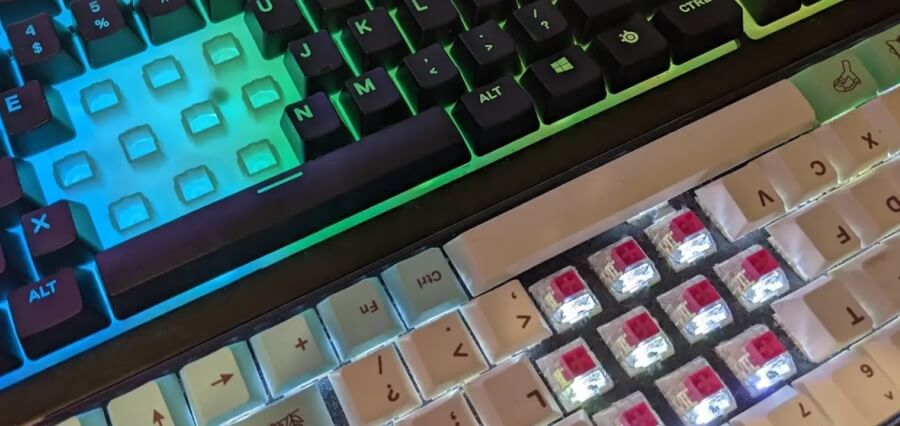

In addition, membrane layer buttons can incorporate backlighting and graphic overlays, additionally improving exposure and functionality in varied settings. This versatility makes sure that devices remain useful and user-friendly, regardless of the setting. Generally, the integration of membrane switches into customer electronic devices dramatically boosts user experience, driving brand loyalty and complete satisfaction in a progressively competitive market.

Cost-Effective Production

Consumer electronic devices makers are regularly looking for methods to balance quality with affordability, and membrane buttons provide an engaging option for cost-effective production. membrane switch. These parts are inherently less complex than standard mechanical switches, which decreases both manufacturing prices and intricacy. The light-weight layout of membrane switches over enables reduced delivery costs and much easier combination into small devices, further boosting their appeal in an open market

Suppliers can produce membrane layer buttons in high volumes, making the most of economies of range. This mass manufacturing capability guarantees consistent high quality while significantly decreasing per-unit expenses. Additionally, the materials utilized in membrane buttons, such as polyester and polycarbonate, are frequently less costly than those needed for standard switch innovations, adding to overall price savings.

The manufacturing procedure for membrane switches usually requires fewer steps and much less labor compared to various other switch kinds. This structured strategy not only saves money on labor costs however also speeds up time-to-market, allowing business to react swiftly to customer demand. The combination of decreased product costs and efficient manufacturing procedures positions membrane layer switches over as a wise investment for manufacturers intending to deliver top notch customer electronics at affordable rate factors.

Style Adaptability and Customization

While standard mechanical switches frequently enforce restrictions on layout as a result of their bulk and needed mounting systems, membrane layer switches offer exceptional adaptability and personalization options for customer electronic devices. This innovative modern technology enables developers to create sleek, inconspicuous user interfaces that can flawlessly integrate right into numerous product aesthetic appeals, from mobile phones visit this site right here to kitchen appliances.

Membrane switches can be produced in practically any form or dimension, enabling manufacturers to customize the design to particular ergonomic and functional requirements. This adaptability not just boosts customer experience yet additionally enables imaginative layouts that straighten with brand identification. In addition, making use of published graphics on membrane layer changes offers the opportunity for dynamic shades and elaborate layouts, which can be easily modified without considerable cost implications.

Furthermore, membrane layer buttons can include several performances into a single layer, decreasing the requirement for numerous elements and streamlining assembly procedures. This structured design strategy reduces space and weight, making it ideal for compact consumer electronic devices. Generally, the style adaptability and customization capabilities of membrane layer switches equip suppliers to introduce, ultimately resulting in even more engaging and straightforward products.

Longevity and Integrity

As modern technology remains to develop, the sturdiness and dependability of membrane buttons have actually become essential factors to consider for producers in the consumer electronic devices market. Membrane layer buttons are designed to endure severe ecological problems, consisting of temperature level variations, dampness, and dust direct exposure. Their durable building and construction usually involves multi-layered materials that provide an effective obstacle against pollutants, guaranteeing durability and consistent performance.

In addition to ecological resistance, membrane layer switches deal superior mechanical reliability. Unlike conventional mechanical switches, which might break over time, membrane changes make use of a sealed style that lessens the threat of mechanical failure. The absence of moving parts not only improves their life-span however additionally reduces wear and tear, making them perfect for high-usage applications.

Furthermore, membrane layer switches can withstand a significant number of actuations without loss of performance, often surpassing millions of cycles (membrane switch). This resilience equates to lower substitute costs and decreased downtime for suppliers and consumers alike. On the whole, the combination of environmental strength and mechanical reliability makes membrane switches a critical selection for consumer electronic devices, guaranteeing that tools remain efficient and operational throughout their desired lifespan

Streamlined Product Advancement

The durability and integrity of membrane layer changes dramatically contribute to why not try this out structured item growth in the consumer electronics sector. By integrating these buttons early in the style process, suppliers can decrease the intricacy and variety of elements needed in their products. Membrane layer switches are compact and light-weight, permitting a lot more efficient space use within tools, which can lead to streamlined assembly procedures.

The ease of making membrane buttons also plays an important function in item advancement. With modern-day printing techniques and products, production can be scaled successfully, reducing lead times and lowering waste. This leads to reduced production prices, enhancing total success.

Verdict

In conclusion, membrane layer switches over substantially enhance consumer electronics by providing an improved customer experience, cost-effective manufacturing processes, and functional design options. The combination of membrane layer switches over stands for a calculated option for suppliers seeking to maximize product style and efficiency.

Membrane layer buttons are significantly identified for their considerable benefits in customer electronics, particularly in enhancing individual interaction and enhancing production procedures. Additionally, the products made use of in membrane layer buttons, such as polyester and polycarbonate, are usually much less expensive than those required for conventional switch modern technologies, contributing to general expense savings.

The production procedure for membrane layer switches over commonly calls for fewer steps and much less labor compared to other button types. Unlike conventional mechanical buttons, which may put on out over time, membrane layer switches make use of a covered design that reduces the risk of mechanical failing.In conclusion, membrane switches over considerably boost consumer electronic devices by giving an improved customer experience, economical production procedures, and versatile layout options.

Report this page